Unlocking One of Australia’s Largest Hard-Rock Lithium Resources

A 50:50 joint venture between SQM and Wesfarmers Limited, this project brings together global lithium expertise and local operational strength to unlock the potential of one of Australia’s most promising hard-rock lithium resources.

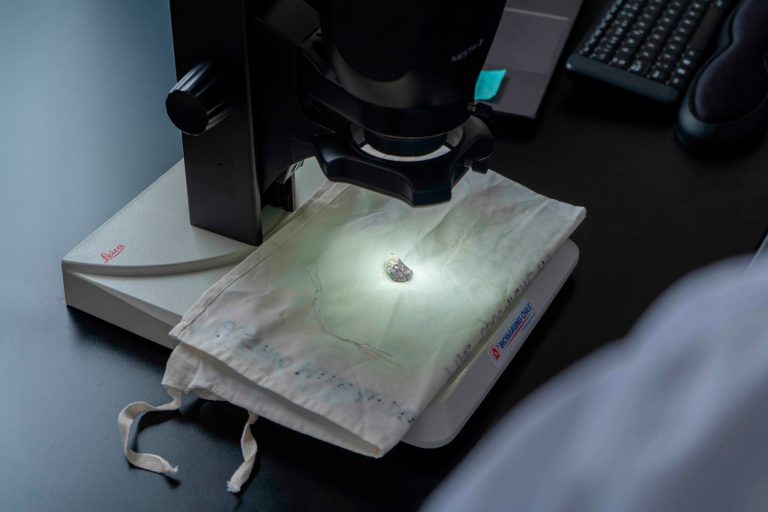

Mining and Processing

The Mt Holland spodumene mine and processor is located approximately 500 km east of Perth and 120 km southeast of Southern Cross, in the Forrestania region, to the west of the Goldfields region in Western Australia.

Expected mine life (years)

50

Joint Venture

50:50

EVs powered

1M

Refinery

The refinery is expected to produce approximately 50,000 tonnes of battery-grade lithium hydroxide in Western Australia, for the global development of lithium batteries.